USTER®JOSSI VISION SHIELD N

Zero-tolerance contamination sorting for flawless end products.

Nonwovens applications such as medical, hygiene and cosmetics demand two non-negotiable rules: zero-tolerance and reliability.

The Uster Jossi Vision Shield N contamination sorter masters this essential job with ease and security. It ensures a perfect experience for the end-user.

Frequently asked questions

Uster Jossi Vision Shield has a capacity of 2,000 kg per hour. The system readily copes with the pace of standard production environments.

Contaminants can hide inside bigger fiber bundles, and this can impact significantly on detection. The ideal location for optimum results is therefore immediately after the fine opener.

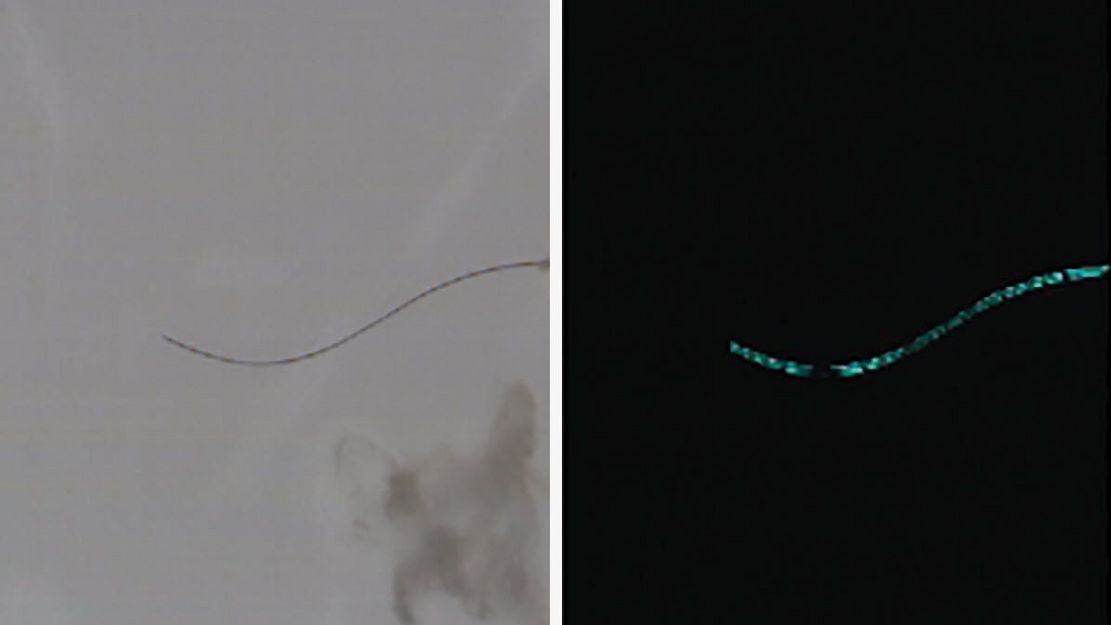

Fine plastic strings are indeed a very difficult type of contamination to eliminate with today’s processes.

Thanks to the Imaging Spectroscopes such contaminants can be reliably detected, regardless of their fineness. The system is also able to detect contamination as fine as a human hair.

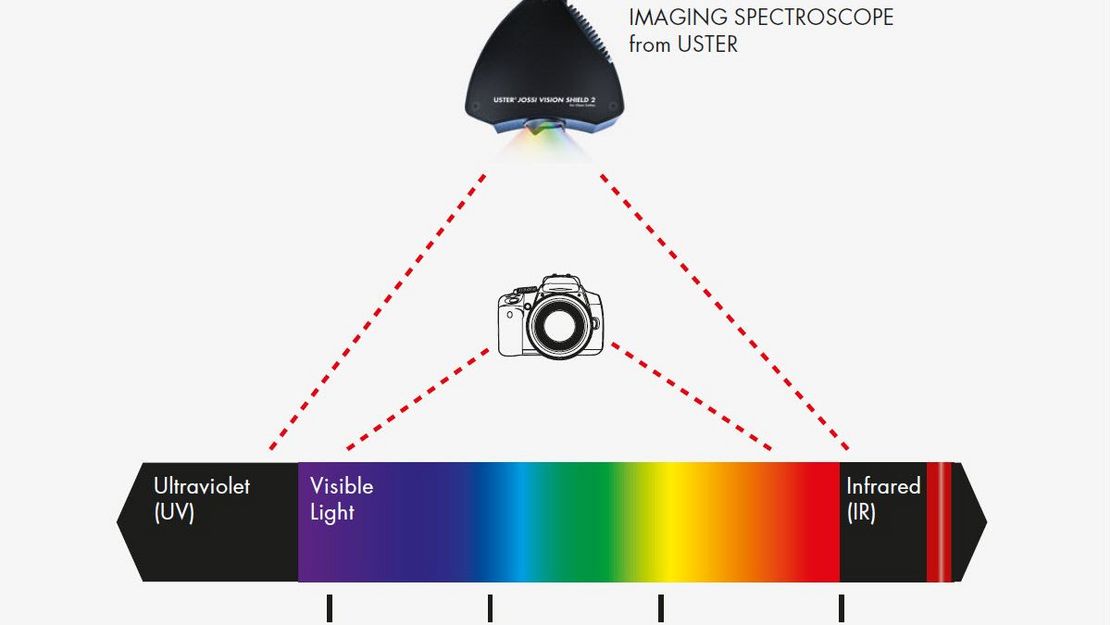

The Uster spectroscopes operate across a much greater wavelength. So they can find contamination even within the ‘invisible’ range of IR and UV light.

Fragments of contamination in light pastel colors and white are also no problem.

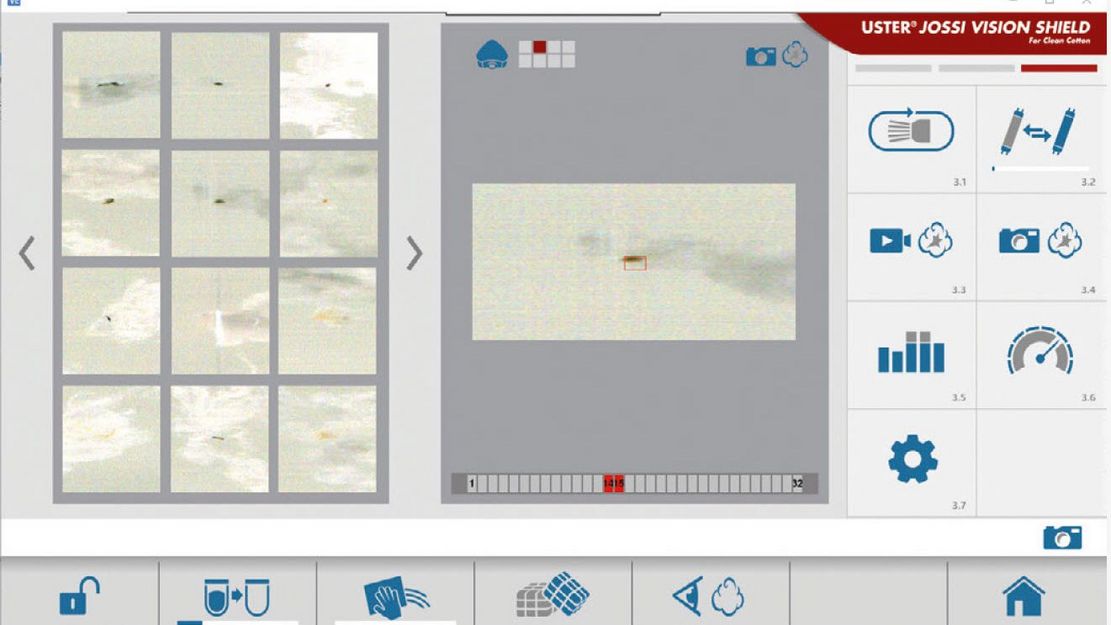

It is possible to view pictures of every ejected contaminant on the touchscreen, to verify that only the required material is removed.

Additionally, through its Quick Teach feature, the system automatically ‘learns’ the correct color of each new raw material lot within seconds. This prevents any annoying false ejections when changing material lots.

The most advanced technology solution for highest detection rate

Uster’s high-end Imaging Spectroscopes for Uster Jossi Vision Shield N are based on 20 years’ experience.

Conventional camera-based systems cannot match the Uster spectroscopes’ performance. Operating across a much greater wavelength, they can find contamination even within the ‘invisible’ range of IR and UV light.

Fragments of contamination in light pastel colors and white are no problem.

Reliable detection of colored and fused fibers, black spots, metal or wood particles, greased deposits, and synthetic fragments.

The Imaging Spectroscopes can detect plastic strings, regardless of their fineness. The system is able to detect contamination as fine as a human hair.

Left: Contaminant (hair) within fiber

Right: Contaminant (hair)

The most advanced technology solution for lowest fiber waste

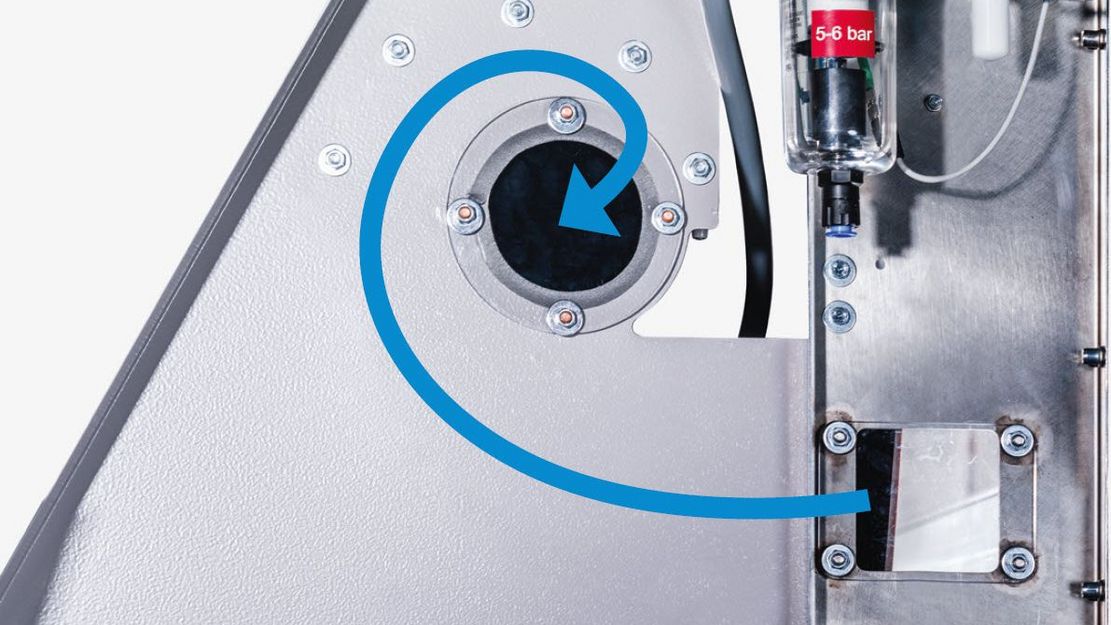

Uster Jossi Vision Shield N continuously measures the velocity of the fiber bundles. Precision valves then match the timing and duration of each ejection, so that only the required amount of contaminant is removed. This minimizes the amount of good material wasted with each ejection.

The unique ‘cyclone’ feature uses a crossflow circulation, preventing waste from getting back into the production flow for efficient and

economical operation.

Through its Quick Teach feature, Uster Jossi Vision Shield N automatically ‘learns’ the correct color of each new raw material lot within seconds. This prevents any annoying false ejections when changing material lots.

It’s possible to view pictures of every ejected contaminant on the touchscreen, to verify that only the required material is removed.

Latest information about Uster nonwovens solutions

Subscribe for product updates, case studies, white papers etc.

Downloads

Our worldwide network

In case you can’t find your country, please refer to our offices here

EURL ALINK Import Export

Uster products (excl. Fabric Inspection)

Cite 300 Logts Elzahir C14 Local 001

M'sila

Phone: +21 35 60 92 00 31

Email: microtech.28(at)gmail.comContact Us

Unionmatex SARL

Uster products (excl. Fiber Cleaning)

18 Rue Abdelouahab Az-Zaqqaq

Belvedere

20310 Casablanca

Phone: +212 522 301 882

Email: contact(at)unionmatex.net

Website: www.unionmatex.net Contact Us

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

Phone: +34 93 7704466

Fax: +34 93 7704467

Email: info(at)fuster.com

Website: http://www.fuster.com Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

Phone: +54 11 4765 4600

Fax: +54 11 4765 1616

Email: gerencia(at)pampakraft.com.ar

Website: http://www.pampakraft.com.ar Contact Us

AST Tech Australasia Pty. Ltd.

13 Chris Court

3037 Hillside, Victoria

Phone: +61 422 39 64 84

Email: adrian(at)astta.com.auContact Us

AST Tech Australasia Pty. Ltd.

Uster products (excl. Fabric Inspection)

13 Chris Court

3037 Hillside, Victoria

Phone: +61 422 39 64 84

Email: adrian(at)astta.com.auContact Us

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Phone: +43 1 31356-0

Fax: +43 1 31356-60

Email: okw(at)kuehnen.com

Website: http://www.kuehnen.com Contact Us

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Phone: +998 71 250 25 65

Email: info(at)art-textile.uzContact Us

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Phone: +998 71 215 90 92

Email: info(at)martex-global.com

Website: http://martex-global.com/ Contact Us

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Phone: +92 21 366 15557

Email: service(at)reespk.com

Website: https://rees-pk.com/ Contact Us

Texcorp Trading Ltd.

117/A Tejgaon I/A

Dhaka 1208

Phone: +88 09612-111177 (Ext. 472)

Email: connect(at)texcorp.netContact Us

Texcorp Trading Ltd.

117/A Tejgaon I/A

Dhaka 1208

Phone: +88 09612-111177 (Ext. 472)

Email: connect(at)texcorp.netContact Us

Eletex Group BV

Uster Fabric Inspection products only

Houtstraat 8

9800 Deinze

Phone: +32 56140201

Email: dirkbenoit(at)eletex.be

Website: www.eletex.be Contact Us

Honoré SAS

Uster products (excl. Fabric Inspection)

10, rue Louis Néel

Synergie Park

59260 Lezennes

Phone: +33 3 20 05 42 50

Email: honore.materiel.textile(at)gmail.com

Website: http://www.honorematerieltextile.fr/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Intercom Ltda.

Calle Hans Kundt 757

Zona Miraflores

La Paz

Phone: +591 2 222 7353

Fax: +591 2 222 1176

Email: intercom(at)intercom.com.bo

Website: http://www.intercom.com.bo Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Cotextil Representaçao Comercial Ltda

Uster products (excl. Fabric Inspection)

Rua Voluntarios da Patria, 1444

Centro

85812-160 Cascavel-PR

Phone: +55 45 99912 6953

Email: jean(at)cotimes.com.br

Website: http://www.cotimes.com.br Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

C.A. Kennedy Inc.

9900 Ray Lawson, Ville d'Anjou

H1J1L8 Quebec

Phone: +1 514 336 72 90

Email: gamicone(at)cakennedyinc.com

Website: www.cakennedyinc.ca Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Comercial Pacific Ltda.

Cordillera 331

Flexcenter D-13

Quilicura-Santiago

Phone: +56 2 2433 3000

Email: aboeck(at)cpacific.cl

Website: http://www.cpacific.cl Contact Us

Uster Technologies (China) Co., Ltd.

Building B, 538 Fengting Avenue,

Suzhou Industrial Park, 215122

Suzhou, Jiangsu Province,

P.R. China

Phone: +86 512- 62742090

Fax: +86 512- 62742521

Email: UTCNT.sales(at)uster.comContact Us

Retexa S.A.S.

Calle 9a Sur 11 111 - Int 128

050022 Medellin

Phone: +57 316 693 45 59

Email: info(at)retexa.com.co

Website: www.retexa.com.co Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Phone: +502 2440 1840

Email: info(at)maprimaq.com

Website: https://www.maprimaq.com/ Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Josef Kopecky

Uster products (excl. Fabric Inspection)

Druzstevni 1406

562 06 Usti nad Orlici

Phone: +420 603 267 897

Email: servis(at)uster.cz

Website: http://www.uster.cz Contact Us

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

Phone: +48 724 914 122

Email: rafal.mierzwa(at)highendvision.plContact Us

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Phone: +43 1 31356-0

Email: okw(at)kuehnen.com

Website: http://www.kuehnen.com Contact Us

Alberto Rigoli Pacca

Uster products (excl. Fabric Inspection)

Urb. Santa Rosa L6

Norberto Salazar N7 - 19

Tumbaco

170184 Quito

Phone: +593 2 2375 123

Email: arigoli(at)lss-ecuador.comContact Us

Otto Seidlitz Representaciones Cia. Ltda.

German Aleman E10-44 y Av. 6 di Diciembre

170504 Quito

Phone: +593 2 2920 362

Email: vecuador(at)seidlitz.com

Website: http://www.seidlitz.com Contact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Fax: +20 3 582 3514

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Catec

Uster products (excl. Fabric Inspection)

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Fax: +20 3 582 3514

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Nobeltex SARL

Uster Fabric Inspection products only

161 Rue du Kiem

8030 Strassen

Luxembourg

Phone: +352 621 640 000

Email: ntawil(at)nobeltex-gies.com

Website: http://nobeltex-gies.com/ Contact Us

Maprimaq, S.A.

Uster Fiber Cleaning products only

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Phone: +502 2440 1840

Email: info(at)maprimaq.com

Website: https://www.maprimaq.com/ Contact Us

Texma Limitada

Uster products (excl. Fiber Cleaning)

Av. El Boqueron # 4-B

Santa Elena

Antiguo Cuscatlan

La Libertad

Phone: +503 2278 4188

Email: texma(at)texma.com.sv

Website: http://www.texma.com.sv Contact Us

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Phone: +7 903 687 34 47

Email: a.filipiev_uster(at)mail.ruContact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

Honoré SAS

10, rue Louis Néel

Synergie Park

59260 Lezennes

Phone: +33 3 20 05 42 50

Fax: +33 3 20 05 15 64

Email: honore.materiel.textile(at)gmail.com

Website: http://www.honorematerieltextile.fr/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Elmatex GmbH Electronic und Maschinen für die Industrie

Uster Fabric Inspection products only

Uerdinger Strasse 149

47799 Krefeld

Phone: +49 2151 36947 0

Fax: +49 2151 36947 29

Email: info(at)elmatex.de

Website: https://www.elmatex.de/ Contact Us

Ingenieurbüro Gerd Schwarz GmbH

USTER® products (excl. Fabric Inspection)

Pestalozzistr. 91

72762 Reutlingen

Phone: +49 7121 93 97 75

Fax: +49 7121 93 97 88

Email: gerd.schwarz(at)schwarz-tex.de

Website: http://www.schwarz-tex.de Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

West Riding Agencies Limited

125 Sapgate Lane

Thornton, Bradford

West Yorkshire BD13 3DY

Phone: +44 1274 428840

Email: emmet(at)WestRidingAgencies.onmicrosoft.com

Website: https://www.westridingagencies.com/ Contact Us

Georgios Tzivelopoulos & Cie E.E. e-TEXELCO

Athanasiou Diakou 15

Marousi 15122, Athens

Phone: +30 210 800 2720

Email: e-texelco(at)texelco.gr

Website: http://www.texelco.gr Contact Us

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Phone: +502 2440 1840

Fax: +502 2440 1830

Email: info(at)maprimaq.com

Website: https://www.maprimaq.com/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Phone: +502 2440 1840

Email: info(at)maprimaq.com

Website: https://www.maprimaq.com/ Contact Us

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

Phone: +48 724 914 122

Email: rafal.mierzwa(at)highendvision.plContact Us

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Phone: +43 1 31356-0

Email: okw(at)kuehnen.com

Website: http://www.kuehnen.com Contact Us

Uster Technologies (India) Pvt. Ltd.

1st Floor, Sam Surya Towers

1168, Avinashi Road,

P. N. Palayam

Coimbatore 641037

India

Phone: +91 422 4500850

Fax: +91 422 4500801

Email: india.sales(at)uster.comContact Us

PT. Gansa Techno Center

Kopo Plaza Blok G-5

Jl. Peta Lingkar Selatan

Kelurahan Sukaasih

Kecamatan Bojongloa Kaler

Bandung

Jawa Barat 40233

Phone: +62 22 607 16 37

Fax: +62 22 607 16 40

Email: info(at)gansa-techno.com

Website: http://gansa-techno.com/ Contact Us

PT. Gansa Techno Center

Kopo Plaza Blok G-5

Jl. Peta Lingkar Selatan

Kelurahan Sukaasih

Kecamatan Bojongloa Kaler

Bandung

Jawa Barat 40233

Phone: +62 22 607 16 37

Fax: +62 22 607 16 40

Email: info(at)gansa-techno.com

Website: http://gansa-techno.com/ Contact Us

West Riding Agencies Limited

125 Sapgate Lane

Thornton, Bradford

West Yorkshire BD13 3DY

Phone: +44 1274 428840

Email: emmet(at)WestRidingAgencies.onmicrosoft.com

Website: https://www.westridingagencies.com/ Contact Us

Weinstein & Namir (1994) Ltd.

Uster products (excl. Fabric Inspection)

47 Vatikim Street

4051447 Even-Yehuda

Phone: +972 54 4332 333

Email: amos.loewidt(at)gmail.comContact Us

Uster Technologies Ltd.

Industrial Park Caesarea North

Bareket 7, POB 3047

Caesarea

Israel

Phone: +972 4 6107 600

Fax: +972 4 6107 626

Email: info(at)uster.comContact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Sacconaghi Monaco SRL

Uster Fabric Inspection products only

Via San Gregorio 12

20124 Milano

Phone: +39 02 29 51 31 33

Fax: +39 02 29 40 94 66

Email: info(at)sacconaghi.it

Website: http://www.sacconaghi.it Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Uster Technologies K.K.

3rd Floor Edge Esaka,

Toyotsu-cho 9-1, Suita

Osaka 564-0051

Japan

Phone: +81 6 6385 3650

Fax: +81 6 6385 3651

Email: osaka.sales(at)uster.comContact Us

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Phone: +998 71 250 25 65

Email: info(at)art-textile.uzContact Us

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Phone: +998 71 215 90 92

Email: info(at)martex-global.com

Website: http://martex-global.com/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Phone: +998 71 215 90 92

Email: info(at)martex-global.com

Website: http://martex-global.com/ Contact Us

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Phone: +7 903 687 34 47

Email: a.filipiev_uster(at)mail.ruContact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Phone: +7 903 687 34 47

Email: a.filipiev_uster(at)mail.ruContact Us

Eletex Group BV

Uster Fabric Inspection products only

Houtstraat 8

9800 Deinze

Phone: +32 56140201

Email: dirkbenoit(at)eletex.be

Website: www.eletex.be Contact Us

Honoré SAS

USTER® products (excl. Fabric Inspection)

10, rue Louis Néel

Synergie Park

59260 Lezennes

Phone: +33 3 20 05 42 50

Email: honore.materiel.textile(at)gmail.com

Website: http://www.honorematerieltextile.fr/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

LH TechTex Sdn. Bhd.

35 Lengkok Berjaya

10350 Penang

Phone: +60 4 228 5850

Email: lhtechtex(at)gmail.comContact Us

Prutech Marketing Snd Bhd

No. 95, Jalan KIP 9

Taman Perindustrian KIP

Kepong

52200 Kuala Lumpur

Phone: +60 3 6273 5886

Email: prutech8(at)gmail.comContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Blutec S.A. de C.V.

Calzada Zavaleta 3920 Local 2

Santa Cruz Buenavista

72170 Puebla, Pue.

Phone: +52 222 888 8624

Email: daniele(at)blutec.com.mx

Website: https://www.blutec.com.mx/ Contact Us

Blutec S.A. de C.V.

Calzada Zavaleta 3920 Local 2

Santa Cruz Buenavista

72170 Puebla, Pue.

Phone: +52 222 888 8624

Email: daniele(at)blutec.com.mx

Website: https://www.blutec.com.mx/ Contact Us

Unionmatex SARL

Uster products (excl. Fiber Cleaning)

18 Rue Abdelouahab Az-Zaqqaq

Belvedere

20310 Casablanca

Phone: +212 522 301 882

Fax: +212 522 301 884

Email: contact(at)unionmatex.net

Website: www.unionmatex.net Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Ingenieursbureau Wendrich & Co B.V.

Deldenerstraat 126

7551 AK Hengelo Ov.

Phone: +31 74 242 22 05

Fax: +31 74 243 48 28

Email: info(at)wendrich.net

Website: http://www.wendrich.net/ Contact Us

AST Tech Australasia Pty. Ltd.

13 Chris Court

3037 Hillside, Victoria

Phone: +61 422 39 64 84

Email: adrian(at)astta.com.auContact Us

AST Tech Australasia Pty. Ltd.

Uster products (excl. Fabric Inspection)

13 Chris Court

3037 Hillside, Victoria

Phone: +61 422 39 64 84

Email: adrian(at)astta.com.auContact Us

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Phone: +502 2440 1840

Email: info(at)maprimaq.com

Website: https://www.maprimaq.com/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Phone: +92 21 366 15557

Fax: +92 21 366 17578

Email: service(at)reespk.com

Website: https://rees-pk.com/ Contact Us

Simag Enterprises FZCO

HD-193, Floor 23

Sheikh Rashid Tower

Dubai World Trade Center

United Arab Emirates

Phone: +97 154 368 11 75

Email: hasan(at)simag-ent.com

Website: www.simag.com.pk Contact Us

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

Phone: +54 11 4765 4600

Email: gerencia(at)pampakraft.com.ar

Website: http://www.pampakraft.com.ar Contact Us

Rheintek Peru S.A.C.

Calle Boulevard 141-145, Ofic. 1001

Urb. Hogares de Monterrico Chico

Santiago de Surco

Lima

Phone: +51 1 683 2301

Email: juan.contreras(at)rheintek-la.comContact Us

Agnessi Trading

1665 Interior 16

Angel Linao Street

Paco

1007 Manila

Phone: +63 2 400 1161

Email: rm.agnessitrade(at)gmail.comContact Us

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

Phone: +48 724 914 122

Email: rafal.mierzwa(at)highendvision.plContact Us

3PM Pawel Prym

Uster Fabric Inspection products only

A. Struga 7/7

90-420 Lodz

Phone: +48 602 381 119

Email: pawelprym(at)gmail.comContact Us

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Phone: +43 1 31356-0

Email: okw(at)kuehnen.com

Website: http://www.kuehnen.com Contact Us

J. Baptista & C.a.L.da

Rua Dos Vanzeleres, 337

4100-484 Porto

Phone: +351 226 061 600

Fax: +351 226 096 412

Email: jbaptista(at)jbaptista.pt

Website: http://www.jbaptista.pt Contact Us

J. Baptista & C.a.L.da

Rua Dos Vanzeleres, 337

4100-484 Porto

Phone: +351 226 061 600

Fax: +351 226 096 412

Email: jbaptista(at)jbaptista.pt

Website: http://www.jbaptista.pt Contact Us

Catec

Uster products (excl. Fabric Inspection)

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Amytex & Partners SRL

Aleea Teisani Nr 296, Camera nr.5

Corp 39, Bloc A67, Etaj 4, Ap.44

Sector 1

014034 Bucuresti

Romania

Phone: +40 726991665

Email: mihaela.ionescu(at)amytex.ro

Website: http://www.amytex.ro Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Prutech Marketing Snd Bhd

No. 95, Jalan KIP 9

Taman Perindustrian KIP

Kepong

52200 Kuala Lumpur

Phone: +60 3 6273 5886

Email: prutech8(at)gmail.comContact Us

Josef Kopecky

Uster products (excl. Fabric Inspection)

Druzstevni 1406

562 06 Usti nad Orlici

Phone: +420 603 267 897

Email: servis(at)uster.cz

Website: http://www.uster.cz Contact Us

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Phone: +43 1 31356-0

Email: okw(at)kuehnen.com

Website: http://www.kuehnen.com Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Corvet Tech Asia Co., Ltd.

Uster products (excl. Fiber Cleaning)

Room #802, Botanic Park Tower 2

GongHangDae-Ro 213, GangSeo-Gu

07802 Seoul

Phone: +82 2 3665 9753

Fax: +82 2 3665 9754

Email: emily(at)corvetko.comContact Us

Corvet Tech Asia Co., Ltd.

Uster products (excl. Fiber Cleaning)

Room #802, Botanic Park Tower 2

GongHangDae-Ro 213, GangSeo-Gu

07802 Seoul

Phone: +82 2 3665 9753

Fax: +82 2 3665 9754

Email: emily(at)corvetko.comContact Us

Paik Inc.

Uster Fiber Cleaning products only

(Yeouido-dong, Donghwa Bldg.), 1008

71, Yeouinaru-ro, Yeongdeungpo-gu

Seoul

Phone: +82 2 783 6977

Fax: +82 2 784 5586

Email: paikinc(at)paikinc.co.krContact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

Phone: +34 93 7704466

Fax: +34 93 7704467

Email: info(at)fuster.com

Website: http://www.fuster.com Contact Us

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

Phone: +34 93 7704466

Fax: +34 93 7704467

Email: info(at)fuster.com

Website: http://www.fuster.com Contact Us

SPJ Holdings (Pvt) Ltd

Uster Fabric Inspection products only

359 Park Road

Colombo 05

Phone: +94 77 342 95 69

Email: spj.holdings(at)gmail.comContact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Uster Technologies AG (HQ)

Sonnenbergstrasse 10

8610 Uster

Switzerland

Phone: +41 43 366 36 36

Email: info(at)uster.comContact Us

Multicom Machinery Taiwan Ltd.

Uster products (excl. Fiber Cleaning)

11 Floor, No. 99 Chung Shan North Road, Sec.2

10445 Taipei

Phone: +886 2 2551 8997

Fax: +886 2 2521 2882

Email: mltcmtwn(at)mltcmtwn.com.twContact Us

Multicom Machinery Taiwan Ltd.

Uster products (excl. Fiber Cleaning)

11 Floor, No. 99 Chung Shan North Road, Sec.2

10445 Taipei

Phone: +886 2 2551 8997

Fax: +886 2 2521 2882

Email: mltcmtwn(at)mltcmtwn.com.twContact Us

Timtex Trading Co.,Ltd.

Uster Fiber Cleaning products only

9F-8, No.413 Lin-Sen North Road

Zhongshan District

Taipei

Phone: +886 02 2560-2945

Email: timtex.taipei(at)timtextw.com.twContact Us

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Phone: +998 71 250 25 65

Email: info(at)art-textile.uzContact Us

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Phone: +998 71 215 90 92

Email: info(at)martex-global.com

Website: http://martex-global.com/ Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

Ulster Service Co.,Ltd

171 Soi Pattanakarn 65 Yaek 5

Khwaeng Prawet, Khet Prawet

10250 Bangkok

Phone: +662 126 5459

Fax: +662 231 5281

Email: thailand.ulster(at)gmail.comContact Us

Avitex Co., Ltd.

Uster Fiber Cleaning products only

No. 16, Soi Krung Thep Kritha 8 Yeak 2 (Pridi)

Hua Mak Sub-District

Bang Kapi District

Bangkok 10240

Phone: +66 8193 14444

Fax: +66 2063 6415

Email: sadisorn(at)avitex.co.thContact Us

Ulster Service Co.,Ltd

171 Soi Pattanakarn 65 Yaek 5

Khwaeng Prawet, Khet Prawet

10250 Bangkok

Phone: +662 126 5459

Fax: +662 231 5281

Email: thailand.ulster(at)gmail.comContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Phone: +33 616 507 498

Email: jlchanselme(at)cotimes-afrique.org

Website: http://www.cotimes-afrique.org/ Contact Us

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Phone: +20 3 583 3301 / +20 3 583 3294

Email: catec(at)catecegypt.com

Website: http://www.catecegypt.com Contact Us

Sebatex

16, Rue de l’Inde

1002 Tunis

Phone: +21 6 9830 10 89

Fax: +21 6 7183 1614

Email: sebatex(at)gnet.tnContact Us

Uster Teknoloji Ticaret A.Ş

Belediye Evleri Mah. 84220 Sok.

İnci Park Sitesi No:2

Çukurova/Adana

Türkiye

Phone: +90 322 454 54 37

Fax: +90 322 454 54 73

Email: tr.service(at)uster.comContact Us

NV. A & A Demeulenaere

Uster products (excl. Fiber Cleaning)

Kruisstraat 1

8840 Westrozebeke

Phone: +32 51 566 921

Fax: +32 51 56 73 31

Email: tony(at)demeulenaerenv.be

Website: http://www.nvdemeulenaere.be Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Phone: +41 79 338 43 68

Fax: +41 61 631 56 54

Email: mailman(at)novac.ch

Website: http://www.novac.ch Contact Us

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Phone: +7 903 687 34 47

Email: a.filipiev_uster(at)mail.ruContact Us

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Phone: +92 21 366 15557

Email: service(at)reespk.com

Website: https://rees-pk.com/ Contact Us

Simag Enterprises FZCO

HD-193, Floor 23

Sheikh Rashid Tower

Dubai World Trade Center

United Arab Emirates

Phone: +97 154 368 11 75

Email: hasan(at)simag-ent.com

Website: www.simag.com.pk Contact Us

Uster Technologies, Inc.

319 Garlington Road,

Suite B4

Greenville, SC 29615

USA

Phone: +1 864 288 9777

Email: utus.sales(at)uster.comContact Us

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

Phone: +54 11 4765 4600

Email: gerencia(at)pampakraft.com.ar

Website: http://www.pampakraft.com.ar Contact Us

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Phone: +998 71 250 25 65

Email: info(at)art-textile.uzContact Us

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Phone: +998 71 215 90 92

Email: info(at)martex-global.com

Website: http://martex-global.com/ Contact Us

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Phone: +39 02 445 29 91

Email: commerciale(at)elettrotex.comContact Us

Representaciones Surmatra, S.A.

Apartado Postal 88056

Prado del Este

1080A Caracas

Phone: +58 212 978 3480

Email: surmatra2(at)gmail.comContact Us

Gia Huy Trading and Technologies Company Limited

7/8/5 Ly Te Xuyen Street, Hamlet 4

Linh Dong Ward, Thu Duc City

Ho Chi Minh City

Phone: +84 28 220 698 68

Email: giahuy.uster(at)gmail.comContact Us

My Hao International Trading Co. Ltd.

Uster products (excl. Fiber Cleaning)

79/13 Pham Thai Buong Street

Phu My Hung, Tan Phong Ward, District 7

Ho Chi Minh City

Phone: +84 8 3943 2228

Email: info(at)myhaovn.com

Website: http://www.myhaovn.com Contact Us

Timtex Trading Co.,Ltd.

Uster Fiber Cleaning products only

9F-8, No.413 Lin-Sen North Road

Zhongshan District

Taipei

Phone: +886 02 2560-2945

Email: timtex.taipei(at)timtextw.com.twContact Us

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Phone: +33 2 32 79 25 25

Fax: +33 2 35 20 82 36

Email: sosea(at)sosea.net

Website: http://www.sosea.net Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Phone: +27 31 208 5472 /+27 74 739 8590

Email: diren(at)allcoreservices.co.zaContact Us

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Phone: +27 31 762 32 76

Email: sporri(at)texmaco.co.za

Website: http://www.texmaco.co.za Contact Us